sale@czbut.com 0519-88402881

0519-88402881

0519-88402881

0519-88402881 0519-88402881

0519-88402881

性能参数 / Performance

| 规格 Specifications | 爪行程t(直径) Jaw stroke t (Diameter) | 最大夹紧力kN Max.gripping force (kN) | 最大撑紧力kN Max.bracing force (kN) | 许用压力Mpa Allowable pressure (Mpa) | 极限转速r/min Limited rotating speed (r/min) | 夹紧范围 Clamping range | 撑紧范围 Bracing range | 净重kg Net weight (kg) |

| BK110SQ | 3.7 | 14 | 7.4 | 0.4~0.8 | 4800 | 2-115 | 15-120 | 6 |

| BK130SQ | 3.2 | 21.2 | 11.5 | 0.4~0.8 | 4800 | 2-130 | 20-140 | 9 |

| BK160SQ | 3.7 | 36.5 | 19.3 | 0.4~0.8 | 4200 | 2-170 | 20-180 | 14 |

| BK200SQ | 4.2 | 53.8 | 30.7 | 0.4~0.8 | 5000 | 5-210 | 20-240 | 22.6 |

| BK250SQ | 4.8 | 73.2 | 46.9 | 0.4~0.8 | 2800 | 10-260 | 30-280 | 33.4 |

| BK320SQ | 8.5 | 116.6 | 78.3 | 0.4~0.8 | 2300 | 10-350 | 40-360 | 73 |

| BK400SQ | 11.5 | 158.2 | 102.9 | 0.4~0.8 | 1000 | 15-420 | 50-430 | 128 |

| BK500SQ | 20.0 | 203.9 | 138.6 | 0.4~0.8 | 1000 | 20-520 | 50-530 | 200 |

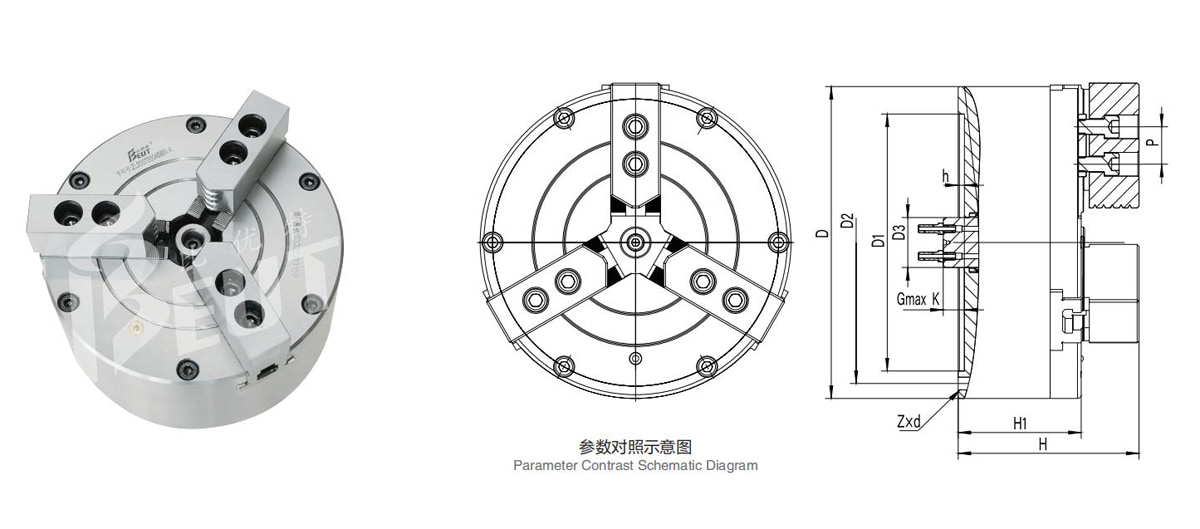

尺寸参数 / Dimensions

| 规格 Specifications | D | D1 | D2 | d | H | H1 | h | Gmax K | Z×d | 动力楔块齿形 | 对应卡爪型号 |

| BK110SQ | 115 | 72 | 102 | 22 | 106 | 81 | 3 | 17 | 3-M8 | 1×53° | BK110Z1 |

| BK130SQ | 135 | 95 | 108 | 25 | 123 | 92 | 4.5 | 15.5 | 3-M8 | 1×53° | BK130Z1 |

| BK160SQ | 172 | 130 | 142 | 25 | 129 | 93 | 4.5 | 17.5 | 3-M8 | 1×53° | BK160Z1 |

| BK200SQ | 210 | 165 | 180 | 32 | 133 | 97 | 5 | 17 | 3-M10 | 1×53° | BK200Z1 |

| BK250SQ | 250 | 206 | 226 | 40 | 145 | 99 | 5 | 17 | 3-M12 | 1×53° | BK250Z1 |

| BK320SQ | 325 | 270 | 290 | 50 | 177 | 116 | 5 | 29 | 6-M12 | 1.5×60° | BK320Z2-60 |

| BK400SQ | 400 | 340 | 368 | 60 | 212 | 141 | 6 | 33 | 6-M16 | 1.5×60° | - |

| BK500SQ | 500 | 440 | 465 | 70 | 256 | 183 | 6 | 34 | 6-M16 | 3×60° | - |

常州比优特机械设备制造有限公司创立于2007年,是一家专业从事各类非标气动卡盘制造的现代技术型企业,专注车床、磨床、加工中心领域十五载,有着成熟的设计制造经验,同时为客户免费提供专业的卡盘选型指导及解决方案。